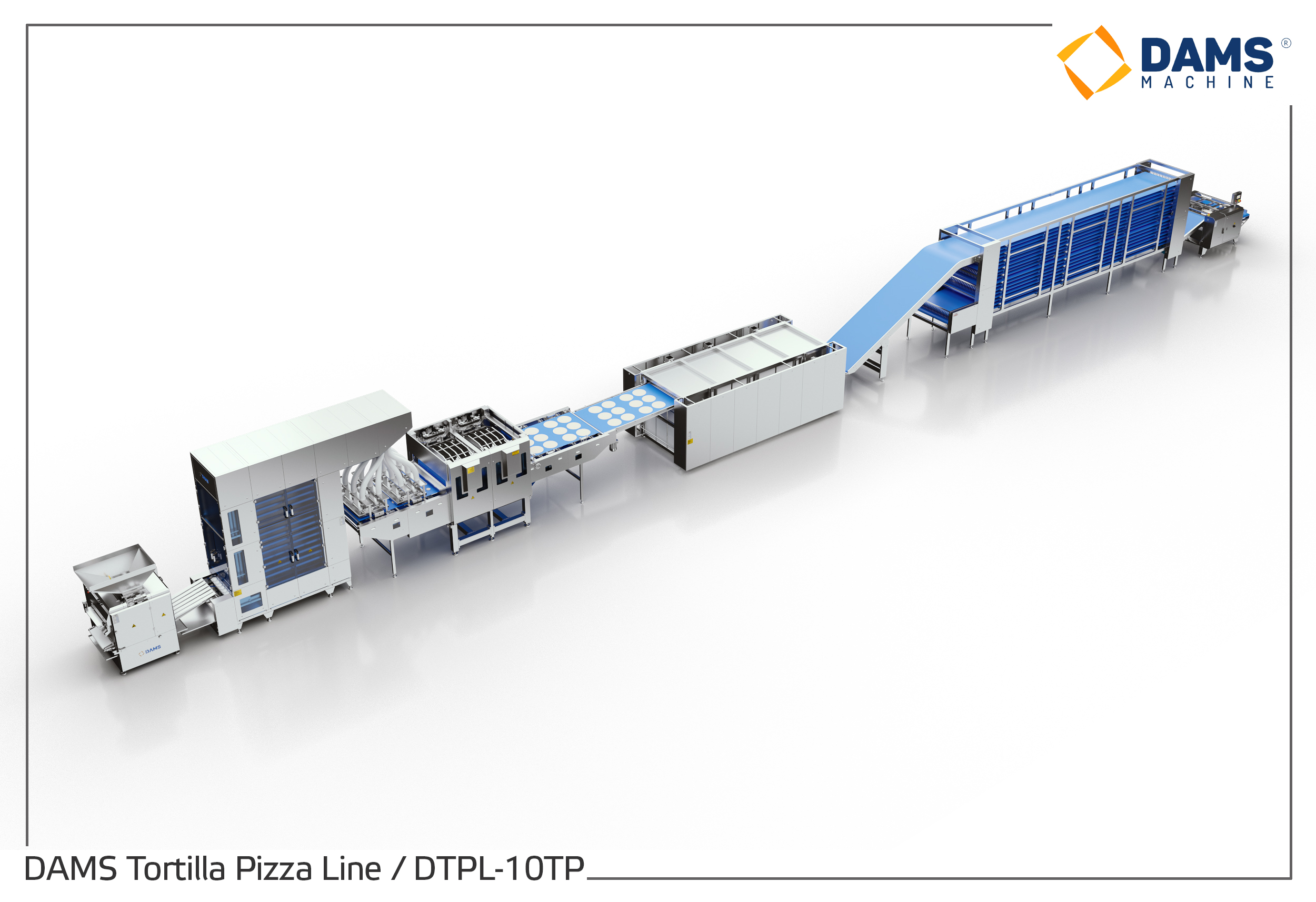

DAMS TORTILLA BREAD LINE 6.000 PCA/H DTPL - 60TP

GENERAL SPECIFICATIONS

|

Capacity |

6,000 pcs/hour |

PressSize |

800mm x 1200mm |

|

Divider and Rounder |

6 |

Oven |

3 Floors |

|

Intermediate Proofer |

8 min. |

Count&Stack |

stacks 4 to 20 pieces. |

|

Press Capacity |

6 pcs |

Control |

PLC – TouchScreen |

|

Product Diameter |

18 – 30cm |

Precision |

±2 (cm) / (gr) |

TECHNICAL DETAILS OF EQUIPMENTS

DIVIDER & ROUNDER

Upto 6000 pcs/hour capacity

Weigh trange 40-140 grams (±2 gr)

6 pieces 50mm diameter pistons

Changable outer drum for different weights

6 row outlet belts

Automatic oil lubrication

Variable speed controls for main drive and rounding unit

Flour duster

Dough bunker capacity is 210 kg

Total power 5 kW

7 inc HMI TouchPanel ,

PLC control

INTERMEDIATE PROOFER

Proofing time 8 minutes (for 6000pcs/hour)

6 pockets stainless steel dough carrier tray

139 pieces active tray

834 active pockets

Removable and washable UHMWPE mesh pockets

2″ roller chainfortray transport

Main frame is stainless steel tube.

Total power 1.5 kW

Easy Access for maintenance

Safety switches on doors

TORTILLA PRESS

800 x1200 top and bottom aluminum press platens

Product diameter range; Ø18cm- Ø30cm, Precision ±2cm

14 strokes per minutes

Presses 6 products in a stroke

36 kW total heating capacity provided by cartridge heaters

PID Temperature controller for optimum heat management

Pneumatic pre-forming unit

Movable upper plate with precise ball screw drive.

Ball screws are drived by servo motors for best accuracy (+-0.01mm)

Product diameter and plate temperature can be changed on HMI touch screen

Teflon press belt with pneumatic auto-tracking device

Heavy duty main frame

Total power 45 kW

Product diameter range; Ø18cm- Ø30cm, Precision ±2c

7 inc HMI Touch Panel

PLC control

OVEN & OVEN FEEDING CONVEYOR

Slat type conveyor, supported1 1/2” roller chain

The fire place is providedwith a heat resistant conveyor for transferring the dough to the baking chamber

The oven cover is made of stainless steel, Insulated by a layer of glass insulation (special type) to minimize heat leakage to the outside

The oven is isolated with 30 cm from both sides for power saving and reducing heat leakage to outside.

12mt long, 1,1mt wide total baking surface (4mt, 3 floor)

3 longidutional burner per floor, total 9 burners

Each floor temperature can be adjusted individually

Each floor conveyor has a motor drive and speed can be adjusted individually

Tortillas slide to bottom floor by stainless steel finger sliders

Total power 7 kW

COOLING CONVEYORS

Stainless steel frame

Inclined modüler infeed belt with non-slip griptop

1100mm wide, open frame modüler belt for efficient cooling

Hingh density PE belt supports

Total 72mt active cooling lenght, (9 floor X 8mt long)

4 minutes cooling time

Product inspection part on last floor

Total power 6 kw

COUNTER-STACKER

Robust Stainless steel frame

3 row of production

3500 pcs/hour capasity per row

1100mm wide infeed belt, non-slip silicone coated

Adjustable infeed belt height

Counts and stacks 4 to 20 pieces depending on thickness

Changable chutes for straight stacking (OPTIONAL)

Pneumatic stack discharge

HMI touch screen

FDA approved food contact surfaces

Outlet conveyor for packaging machines (OPTIONAL)

Total power 2 Kw

MODULER CURVE CONVEYOR

Stainless steel frame

Curve moduler belt

350mm wide

Hingh density PE belt supports

Total power 0,37 kW